- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

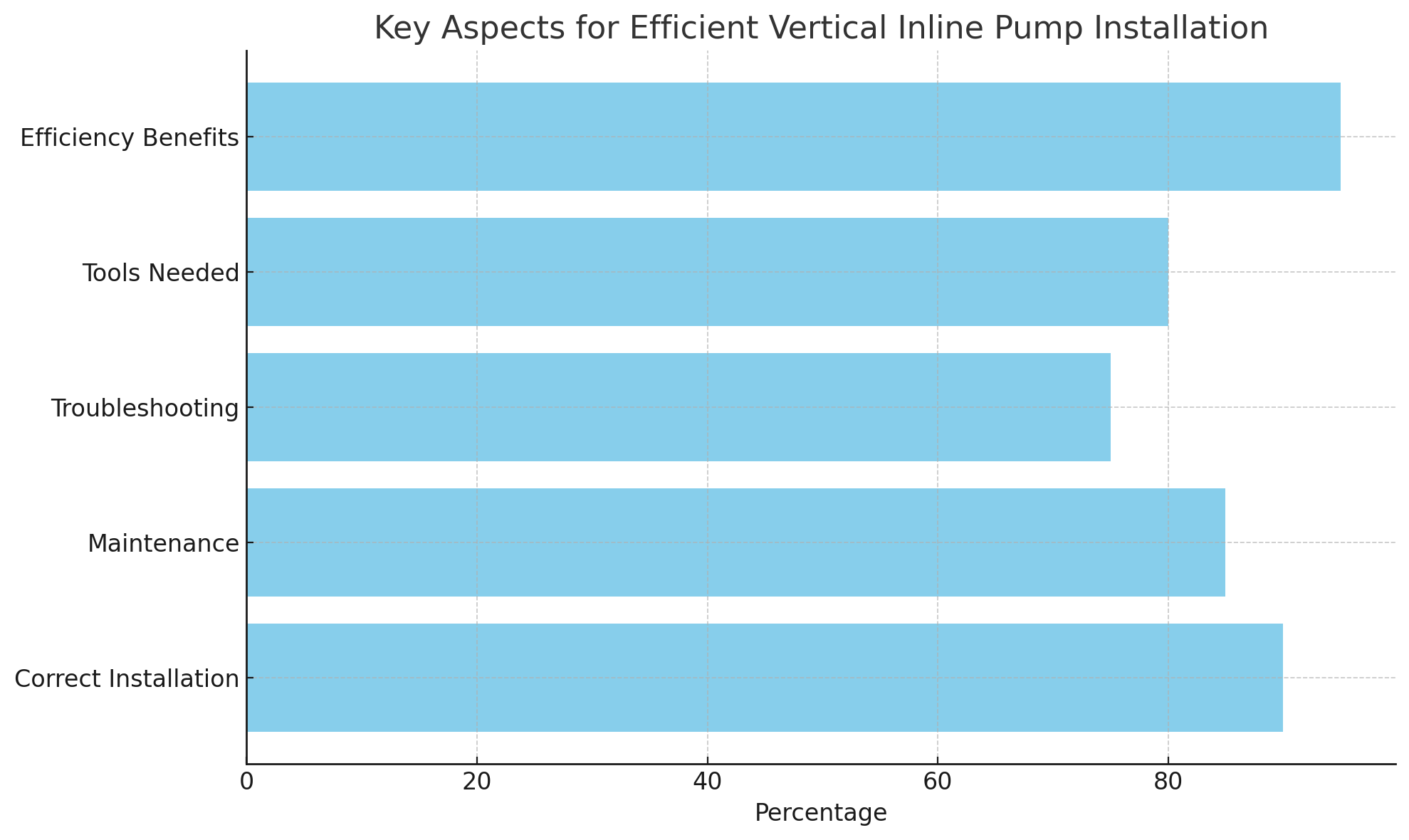

Vertical inline pumps are crucial for fluid movement in many industrial settings. They offer an efficient, space-saving solution, especially in tight spaces. However, their long-term performance depends on correct installation.

In this guide, you’ll learn the step-by-step process for installing a vertical inline pump. We’ll focus on maximizing its efficiency, minimizing downtime, and ensuring reliability.

A vertical inline pump is a type of centrifugal pump that features both the inlet and outlet aligned vertically along a single axis. This design allows the pump to be installed directly in the pipeline, making it an ideal choice for applications where space is limited. Unlike horizontal pumps, which require more space for installation and alignment, vertical inline pumps offer significant space-saving advantages.

These pumps are primarily used in industrial processes where high flow rates and low to medium-pressure systems are common, such as in HVAC systems, water supply networks, and industrial water treatments. Vertical inline pumps are efficient, compact, and easy to maintain, making them a popular choice in various industries.

● Space-Saving Design: The compact vertical configuration allows for installation in tight spaces, reducing the need for large infrastructure modifications.

● Ease of Installation and Maintenance: With fewer components to assemble compared to other pump types, vertical inline pumps are quicker to install and simpler to maintain.

● Efficiency: Their direct alignment with the pipeline minimizes the energy loss that occurs during fluid transfer, resulting in better energy efficiency compared to horizontal pumps.

Vertical inline pumps provide a more streamlined installation process, particularly in spaces where horizontal pumps would take up too much room. In addition, their design helps in maintaining the efficiency of the system by reducing the need for additional fittings or supports. This translates into reduced maintenance costs and longer pump life.

Before starting the installation of your vertical inline pump, it's essential to make the right preparations to ensure a smooth and efficient setup.

Selecting the right location for the installation is crucial to avoid future operational issues. The area must be stable, level, and capable of supporting the pump’s weight. Additionally, ensure that the site allows for easy access to the pump for regular maintenance.

● Space Requirements: Check that the area provides sufficient clearance around the pump to facilitate routine maintenance and ensure proper ventilation.

● Environmental Considerations: Avoid locations exposed to extreme temperatures or corrosive conditions unless the pump is specifically designed to handle such environments.

Ensure that all the necessary tools are at hand before starting the installation. Common tools required for installing a vertical inline pump include:

● Precision Straight-Edge: For checking the alignment of the baseplate.

● Dial Indicators and Magnetic Bases: Used for ensuring correct shaft alignment.

● Leveling Equipment: To guarantee the pump is positioned correctly.

Additionally, you will need some basic hand tools like wrenches, torque wrenches, and screwdrivers.

Installations often involve heavy lifting and working with potentially hazardous equipment, so it’s essential to follow safety measures. Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and safety shoes. Follow all lockout/tagout procedures to prevent accidental electrical discharge or fluid leaks during the installation process.

The foundation is the base upon which the pump will sit. An unstable or uneven foundation can lead to misalignment and premature wear of the pump.

● Cleaning the Baseplate: Thoroughly clean the foundation and ensure that the surface is smooth and free from debris. A clean, dry surface ensures a strong bond for the grout.

● Leveling the Baseplate: Using a precision straight-edge and machinist level, ensure the baseplate is level to within 0.002 inches. This step is crucial to ensure proper alignment of the pump shaft and prevent unnecessary wear on the bearings.

Alignment between the pump and motor shaft is critical to ensure optimal performance and prevent vibrations. Misalignment can cause excessive wear on the bearings, seals, and shafts, leading to premature failure.

● Using Dial Indicators: To align the motor and pump shaft precisely, use dial indicators to measure any deviations.

● Laser Alignment: For greater accuracy, you can use laser alignment tools to achieve perfect motor-to-pump shaft alignment.

Once the pump and motor are properly aligned, the next step is connecting the pump to the piping system. Ensure that the suction and discharge pipes are installed according to the correct specifications to avoid unnecessary strain on the pump.

● Ensure No Pipe Stress: When connecting the pump, make sure that the pipes are aligned naturally with the pump flanges. Any misalignment could result in excessive stress on the pump casing, leading to premature failure.

● Using Flexible Connectors: Installing flexible connectors between the pump and piping will help reduce the vibration transfer, enhancing the overall pump performance.

Proper installation of mechanical seals or packing is crucial to prevent fluid leakage at the shaft. Ensure that the seal chamber is clean and the shaft surface is smooth.

● Lubrication: Apply the appropriate lubrication to the shaft and sealing components before installation to ensure smooth operation and to extend the lifespan of the seals.

● Correct Packing Installation: If using packing instead of mechanical seals, ensure that the packing rings are installed evenly and staggered to prevent leakage.

After mechanical setup, it’s time to connect the pump’s motor to the electrical power source. Ensure that the motor specifications match the power supply.

● Check Motor Voltage: Verify that the motor is wired correctly for the specified voltage, phase, and frequency. Incorrect wiring can damage the motor or result in inefficient operation.

● Rotation Direction: Prior to coupling the motor and pump, verify the correct rotation direction by briefly energizing the motor. Incorrect rotation can cause immediate damage to the pump components.

Once the pump is installed and connected, it's time to perform several critical tests to ensure the system is working properly.

Before starting the pump, double-check the following:

● Pump Rotation: Ensure that the motor is rotating in the correct direction.

● Valve Positions: Confirm that all valves are in the appropriate position—suction valve open and discharge valve closed.

● Electrical Parameters: Monitor the motor’s amperage, voltage, and current during the first startup.

● Excessive Vibration: This could be a sign of misalignment or an issue with the pump foundation. Recheck alignment and the foundation if necessary.

● Leaks: Inspect all seals and connections for any signs of leakage during the initial run.

● Noise: Unusual sounds could indicate mechanical issues such as misalignment or bearing wear.

If the pump fails to perform as expected, common troubleshooting steps include:

● Check for Pipe Blockages: Ensure that the suction and discharge pipes are free of debris.

● Verify Pump Alignment: Use dial indicators or laser alignment to check for any misalignment that could cause excessive wear.

Regular maintenance is essential to ensuring the long-term reliability and efficiency of your vertical inline pump.

Schedule regular inspections to identify any wear on moving parts such as bearings and seals. Keep track of performance metrics like flow rate, pressure, and motor amperage to spot any irregularities early.

Keep all moving parts well-lubricated to reduce friction and wear. Clean the pump regularly to prevent buildup that can hinder performance.

● Monitor Performance: Regularly monitor the pump’s performance to detect any potential issues before they result in a failure.

● Use Diagnostic Tools: Utilize diagnostic tools to assess the pump’s condition and make adjustments as needed.

To ensure the pump continues to perform at its best, follow these best practices for optimizing efficiency:

Ensure that the pump is always aligned properly and operating within its design parameters. Regularly check the performance curve to make sure the pump is running efficiently and avoid overloading the system.

A well-maintained and properly installed pump can significantly reduce energy consumption, leading to lower operational costs.

Consider retrofitting older pumps with more efficient models or upgrading components to improve energy efficiency and reduce downtime.

Proper installation and regular maintenance of vertical inline pumps are essential for maximizing their efficiency. By following this step-by-step guide, you can enhance the reliability and performance of your industrial water pump system. TQ PUMP offers reliable solutions that ensure efficient operation and long-term value, with professional support for installation and maintenance services.

A: A vertical inline pump is a type of centrifugal pump designed to be installed directly in the pipeline. It's often used in industrial water pump systems to move fluids efficiently in confined spaces.

A: Proper installation ensures maximum efficiency, reduces wear, and prevents alignment issues in industrial water pump systems, leading to longer lifespan and better performance.

A: Regular inspections, lubrication, and alignment checks are essential for maintaining vertical inline pumps. Proper maintenance keeps industrial water pump systems running smoothly and efficiently.

A: To install a vertical inline pump, you'll need precision tools like a straight-edge, machinist level, dial indicators, and proper safety equipment to ensure correct alignment and safety during installation.

A: Common issues include leaks, vibration, and misalignment. Ensure proper alignment, check for loose connections, and regularly inspect seals to resolve problems with industrial water pumps effectively.